Rendering problems can lead to serious damage if ignored — from cracks and stains to peeling surfaces that allow moisture to seep in. External rendering plays a crucial role in protecting your home from the elements, improving energy efficiency, and boosting kerb appeal. In this post, we’ll explain the most common rendering problems, what causes them, how to fix them — and when it’s time to re-render completely.

Table of Contents

Cracking in the Render

Cracks are the number one visible sign that something’s wrong with your rendering system.

Not all cracks mean failure — but most cracks, left untreated, will grow and let in water.

Causes of Render Cracks:

- Building movement or settlement

- Thermal expansion and contraction

- Inadequate mesh/reinforcement during application

- Drying too fast due to hot weather

Types of Cracks:

- Hairline cracks: superficial but allow water in

- Spider cracks: often from fast drying or weak mix

- Large structural cracks: may indicate deeper substrate issues

Fix or Replace?

- Hairline: flexible filler + sealant (temporary)

- Spreading or deep cracks: professional render repair or full re-render

Water Ingress and Damp Behind Render

Render is meant to repel water. But once cracked or poorly sealed, it can trap moisture inside your walls, leading to:

- Mould growth inside the home

- Damp patches on internal plaster

- Rotting timber or insulation underneath

Common Causes:

- Blocked or missing weep vents

- Gaps around windows or wall joints

- Render applied in wet conditions

What You Can Do:

- Identify and fix any sources of water ingress

- Replace damaged render sections

- Re-render with breathable systems (e.g., silicone-based)

The Energy Saving Trust explains how breathable external render systems can improve insulation while preventing trapped moisture — ideal for solid wall properties.

Algae, Staining and Discolouration

Green or black staining is very common on north-facing walls. Algae loves damp, shaded surfaces — and poorly maintained render is the perfect host.

Causes:

- Poor drainage or splashback from the ground

- Lack of overhang on the roofline

- Blocked gutters

Solutions:

- Softwash or pressure wash render (if safe for material)

- Treat with biocide cleaner

- Apply self-cleaning topcoat or re-render with algae-resistant finish

Peeling, Flaking or Powdery Surfaces

Render that’s coming off in flakes or chalking when touched has likely degraded due to:

- UV exposure breaking down the top layer

- Moisture trapped behind the surface

- Incompatible paint or coatings applied

Signs of serious failure:

- Topcoat detaching from the base layer

- Soft, crumbly texture when rubbed

- Pieces falling away after heavy rain

Fix or Re-render?

- Small sections may be patched

- Full wall failure = time to re-render using a modern system (e.g., monocouche or silicone)

Poor Application by Previous Contractors

Not all renderers are equal — and sadly, poor workmanship is a leading cause of early render failure.

Common Mistakes:

- Thin, uneven application

- No mesh used to reinforce edges or stress points

- Rendering done in freezing, damp, or hot conditions

- Wrong render type for the substrate

Red Flags to Look For:

- Visible trowel marks or texture inconsistency

- Uneven colour fading or patches

- No expansion joints on long walls

What to Do:

- Get a proper inspection (we do free site visits)

- Strip back poorly bonded render

- Re-render using correct method + high-quality materials

Movement in the Wall or Substrate

Sometimes it’s not the render’s fault — the wall underneath may be moving or deteriorating.

This is common in:

- Old stone properties

- Homes built on clay or shifting soil

- Houses with historic damp damage

What to Look For:

- Long diagonal cracks from corners of windows or doors

- Bulging or concave render sections

- Separation between render and skirting

If the substrate moves, even the best render won’t hold. Fixing the wall structure comes first then re-rendering can be done properly.

FAQ: Rendering Problems

How long should external render last?

Most modern systems (monocouche, silicone) last 20–30 years when applied correctly and maintained.

Can I patch render myself?

Small repairs in sand and cement render, yes — but matching texture and colour is hard.

For larger repairs, hire a pro to avoid making the problem worse.

Should I repaint render or re-render it?

If the render is sound, repainting is fine.

If it’s flaking, cracking, or holding damp re-rendering is the safer, longer-term solution.

What’s the best render type to avoid future issues?

Silicone-based render is the most durable and breathable for UK homes. It’s flexible, algae-resistant, and comes in colour-matched finishes.

How to Prevent Rendering Problems

- Clean gutters and downpipes every 6 months

- Inspect render each spring and autumn for cracks

- Keep ground soil and vegetation 150mm below DPC

- Don’t use harsh pressure washing

- Recoat render every 10–15 years if needed

Regular maintenance keeps your render looking sharp and performing well.

If you want to learn more about Our Rendering Services or need advice? Contact Us for a free no obligation quote.

Conclusion

Render is your home’s first line of defence and when it fails, the consequences can go far beyond the surface. Cracking, staining, and damp patches are more than just cosmetic issues — they’re signs your property may be vulnerable.

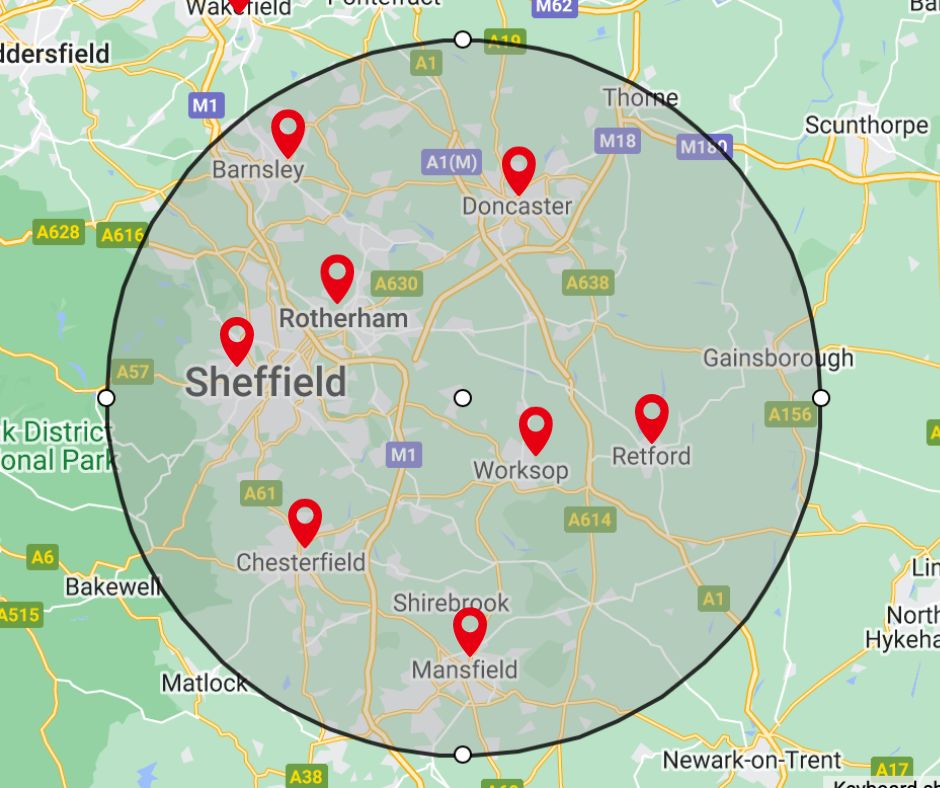

If you’ve spotted signs of render failure, don’t wait. At P3 Plastering, we’ve helped hundreds of Sheffield homeowners restore their walls with long-lasting, weather-resistant finishes.

✅ Worried about your render?

📞 Contact P3 Plastering for a free inspection and expert advice today.